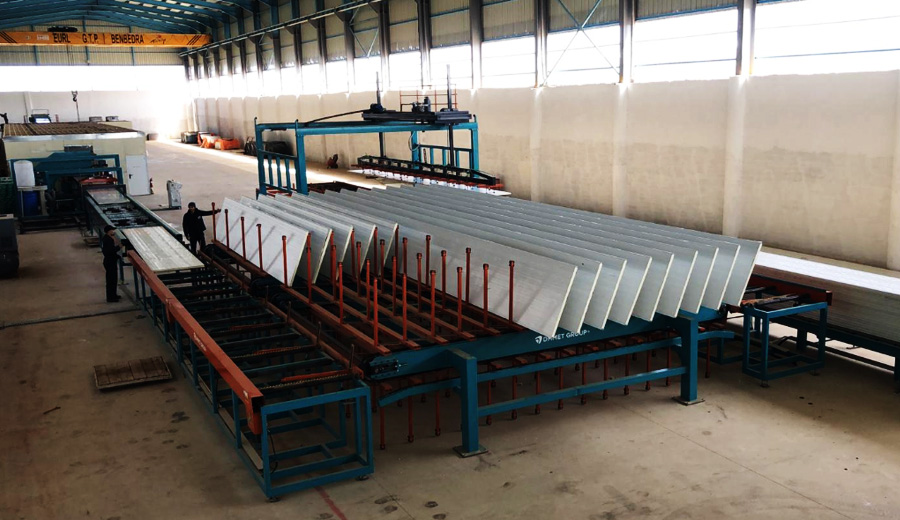

PU - PIR Sandwich Panel Production Line

PU - PIR Sandwich Panel Production Line

Production Type : Continuous and automatic production

Specification of Metarial : 0.3 - 0.8 mm

Width of Metarial : 1250 mm Max

Main Power : 240 kW

Total Power : 360 kW

Structure of Roll Forming Machine : Upper and lower pressing group producing with the pu complex mainframe

Forming System : Continuous and automatic foaming, foaming capacity can be stepless adjustable.

Foaming Thickness :20 - 300 mm

Speed : 0 - 16 mm / min

Way of the Controlling : Siemens PLC Computerized controling

Total Weight : about160 Ton

Total Lenght : about 85 meter

Our contionuous PUR / PIR sandwich panel production line is already recognized its value by exporting to European country with CE and other major sandwich panel producing companies at domestic and foreign, DMMET, we will keep trying for development in accordance with customer’s needs for the high quality sandwich panels.

APPLICATION of the PU-PIR PANEL PRODUCTION LINE

This production line is suitable for manufacturing socket type ( wall plate panel ) and lapped type ( roof tile panel ) pu sandwich panels.

FLOW CHART

Uncoiler - Feeding Guide - Protective Film Coating - Roll Forming Machine - Rolling Conveyer - Steel Pre-Heating - Foaming Machine - Double Belt Pressing Machine - Rolling Conveyer - Auto Fly Cutting To Length - Runout Table - Auto Vacuum Stacker - Auto Packing Machine

Other Machines

Pu- Pır Sandwich Panel Production Lines

Trapezoidal Sheet Metal Production Line

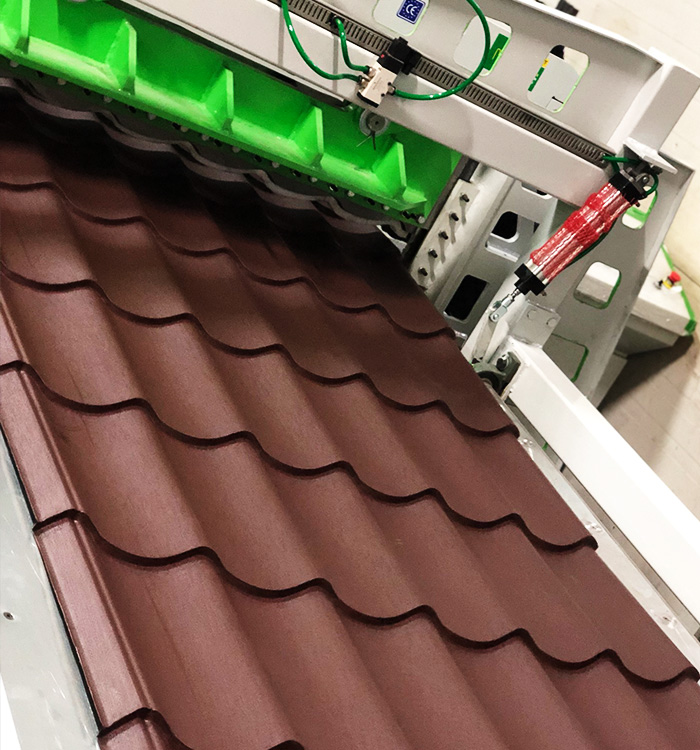

Metal Tile Roof Production Lines

Sheet Length Cutting Production Line

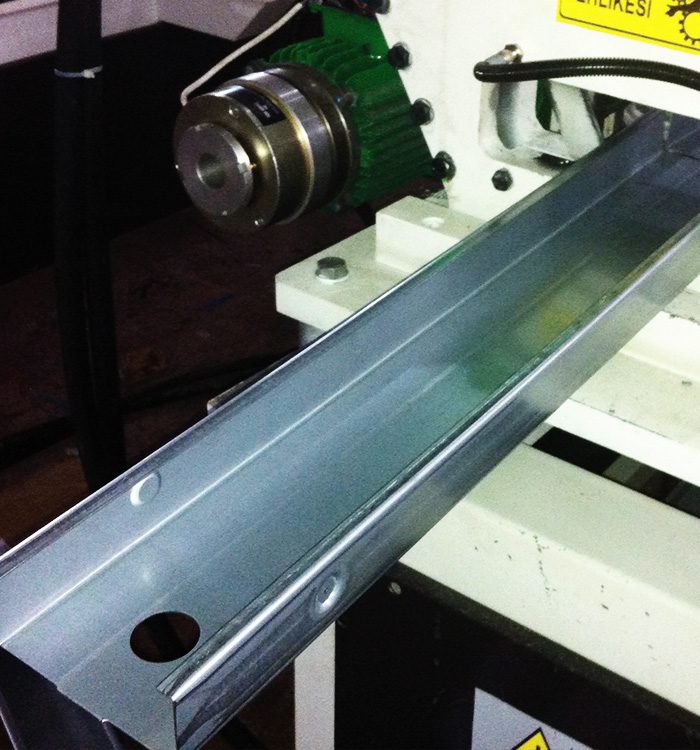

Flexible U-C Purlin Machine